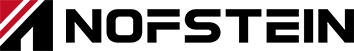

Pehmeä laajennettu modifioitu PTFE -arkki grafiittia, ptfe teflon tiivistys

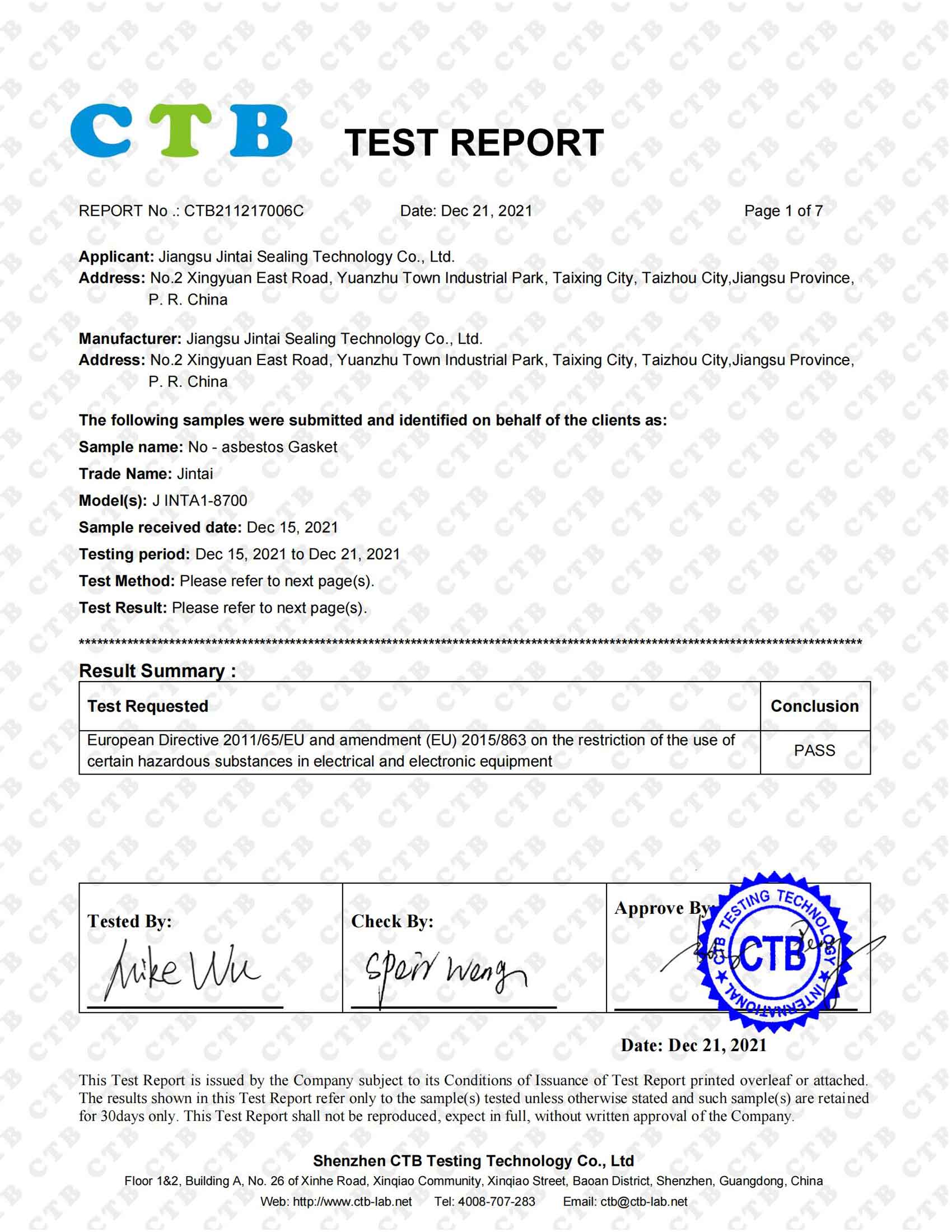

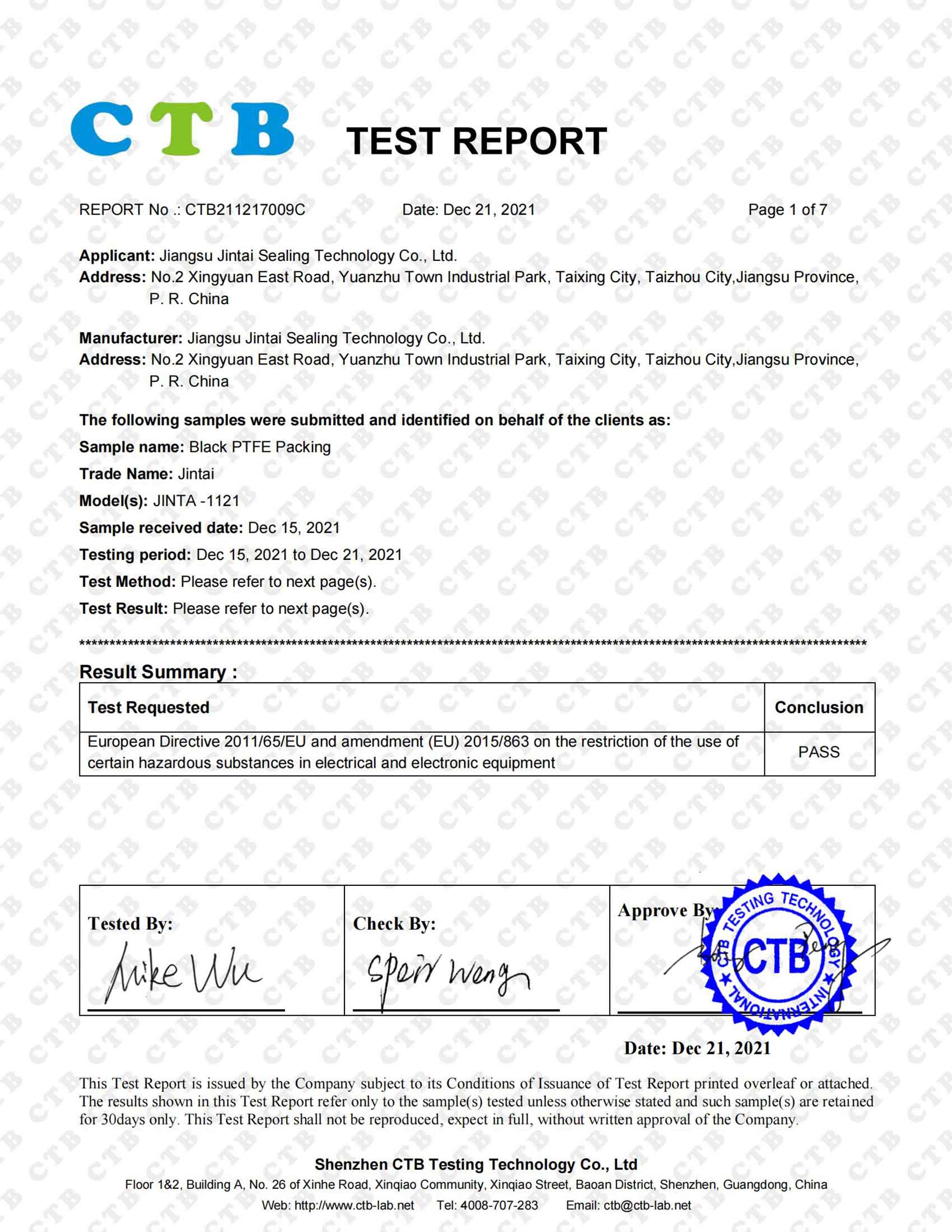

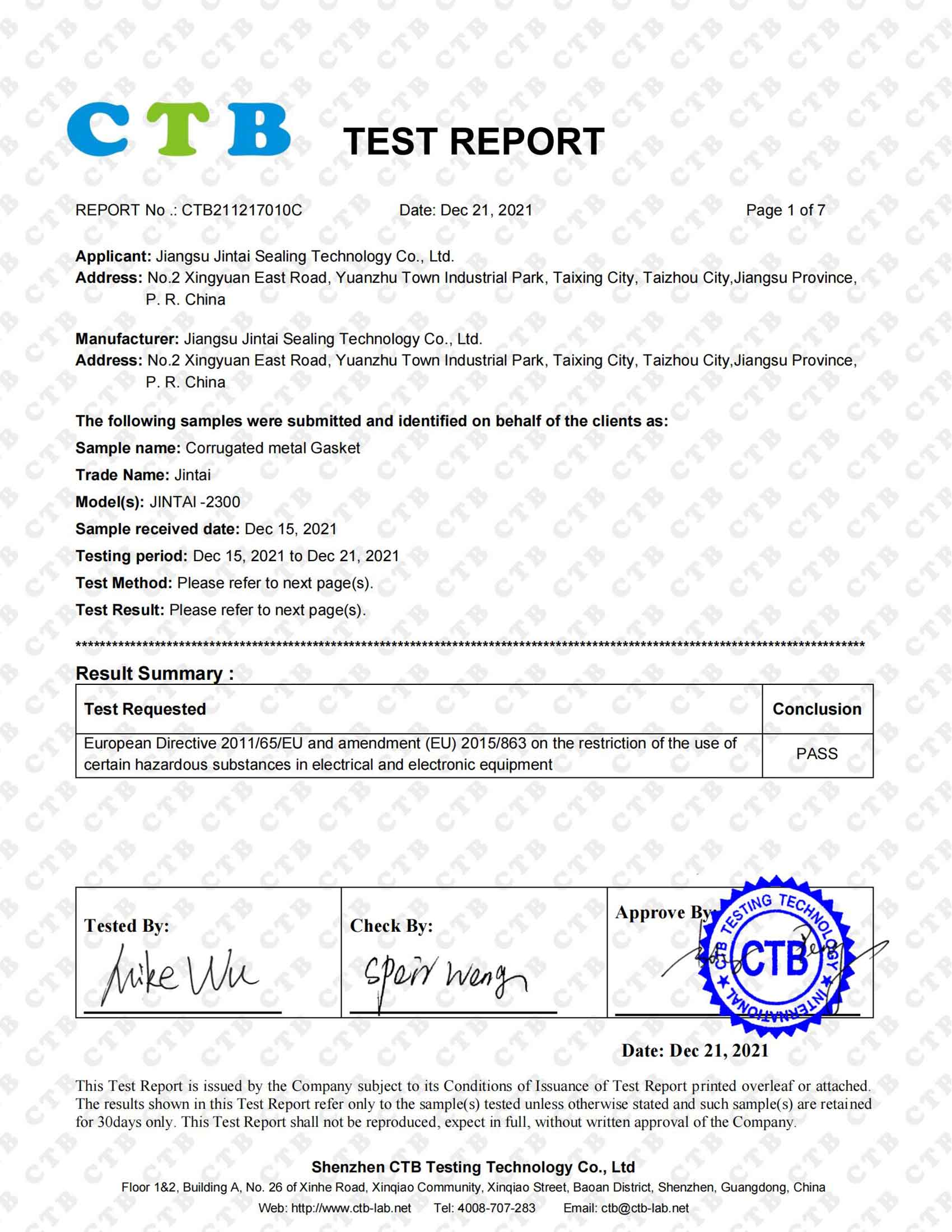

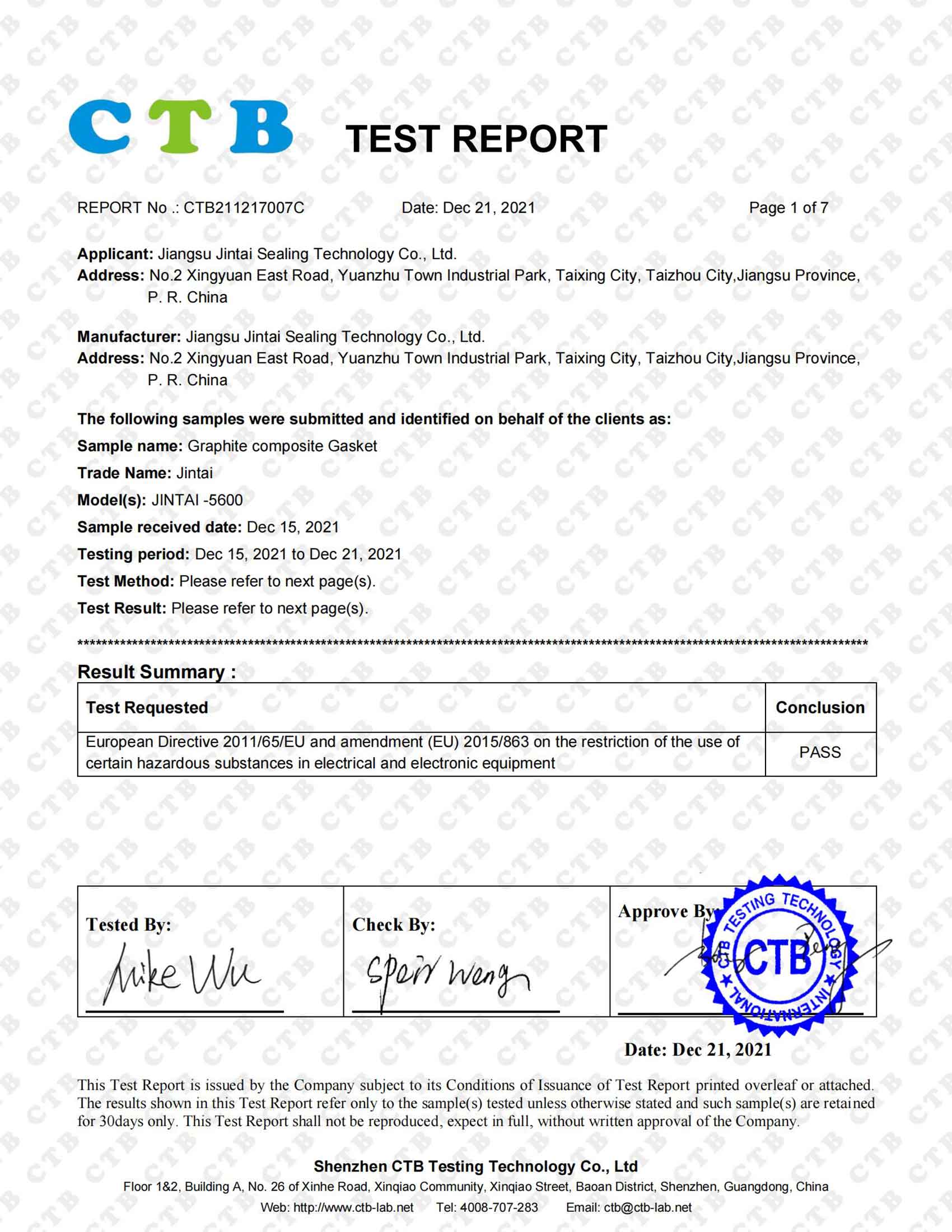

Pehmeä laajennettu muokattu PTFE -arkki grafiittia on valmistettu puhtaasta polytetrafluorietyleenistä (PTFE), joka on modifioitu grafiittia. Siinä on erinomainen kemiallinen vastus, korkea lämpötilankestävyys ja alhainen kitkakerroin, ja se voi ylläpitää vakaata suorituskykyä äärimmäisissä lämpötilassa -ajoissa -190 -260 ℃. Tuote on korroosionkestävä, ikääntymiskestävä ja tarttumaton, ja se sopii ankariin ympäristöihin, kuten vahvoihin hapoihin, vahvoihin emäksisiin ja orgaanisiin liuottimiin. Grafiitin lisääminen parantaa edelleen materiaalin lämmönjohtavuutta ja puristusvastusta, jolloin se toimii hyvin korkeassa lämpötilassa ja korkeassa paine -olosuhteissa. Sitä käytetään laajasti kemiallisissa, lääkkeissä, elintarvikkeiden jalostuksessa, ilmailu- ja muissa toimialoilla, etenkin laippayhteyksillä, putkilaitteilla ja laitetiivisteillä, joilla on erittäin korkeat tiivistysvaatimukset. Se noudattaa FDA- ja ROHS -standardeja.

Erittely

Tuotteen esittely:

Suorituskykyinen grafiitti-infusoitu laajennettu PTFE-arkki erinomaiseen tiivistykseen

Meidän Pehmeä laajennettu muokattu PTFE -arkki grafiittia on edistyksellinen tiivistysratkaisu, joka on suunniteltu vaativiin teollisuussovelluksiin. Tämä innovatiivinen materiaali yhdistää PTFE: n poikkeukselliset ominaisuudet grafiitin voiteluaineisiin, jotka toimittavat vertaansa vailla suorituskykyä korkean lämpötilan ja syövyttävissä ympäristöissä.

Grafiittia täytetty laajennettu PTFE-arkki tarjoaa erinomaisen kemiallisen resistanssin, erinomaisen puristumisen ja erinomaisen lämpöstabiilisuuden. Sen ainutlaatuinen muokattu koostumus parantaa hiipivävastusta säilyttäen samalla tehokkaan tiivistymiseen tarvittavan joustavuuden.

- Parannettu lämmönjohtavuus: Grafiittikiukkaset parantavat lämmön hajoamista

- Vähentynyt kitka: Itsevoitelevat ominaisuudet minimoivat kulumisen

- Kemiallinen inertti: Keskeistyy käytännöllisesti katsoen kaikki teollisuuskemikaalit

- Erinomainen pakkauksen palautuminen: Ylläpitää tiivisteen eheyttä painevaihteluissa

- Lämpötilankestävyys: Suorita -268 ° C -315 ° C (-450 ° F -600 ° F)

| Parametri | Arvo |

|---|---|

| Materiaali | Muokattu PTFE grafiittia |

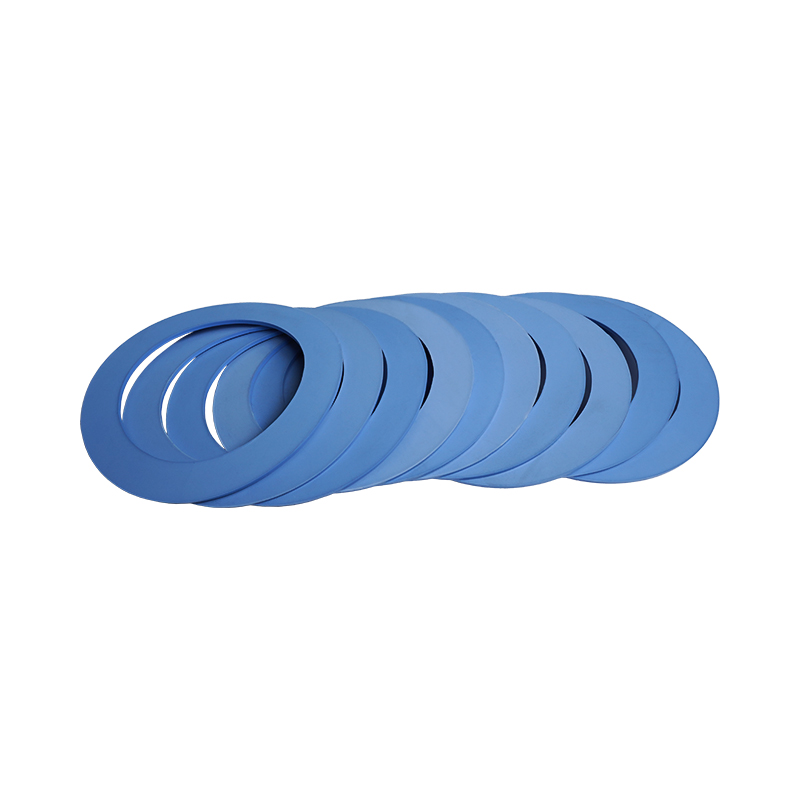

| Paksuusalue | 0,5–6,0 mm |

| Tiheys | 0,6-1,2 g/cm³ |

| Vetolujuus | 5-15 MPa |

| Puristusjoukko | 15-30% (huoneenlämpötilassa) |

| Lämmönjohtavuus | 0,35 w/mk |

| Painekunta | Jopa 200 baaria (paksuudesta riippuen) |

Graphite-PTFE-komposiittiarkki on ihanteellinen:

- Kemiallinen prosessointi: Tiivisteet pumppuille, venttiileille ja reaktorille

- Sähköinen tuotanto: Turbiinien ja lämmönvaihtimien tiivisteet

- Öljy ja kaasu: Laipan tiivisteet jalostamoissa ja putkistoissa

- Farmaseuttinen: Saniteetti tiivisteet puhdasta prosessia varten

- Ruoanjalostus: FDA-yhteensopiva tiivistysratkaisut

- Automotive: Korkean lämpötilan moottoritilat

Miksi valita grafiitti PTFE -arkki?

Verrattuna tavanomaisiin PTFE -arkkeihin, muokattu versio tarjoaa:

- 30% parempi ryömintävastus

- Parannettu kuormituskyky

- Vähentyneitä kylmävirtausominaisuuksia

- Parannettu tiivistymisteho lämpöpyöräilyn alla

- Pidempi käyttöikä aggressiivisissa ympäristöissä

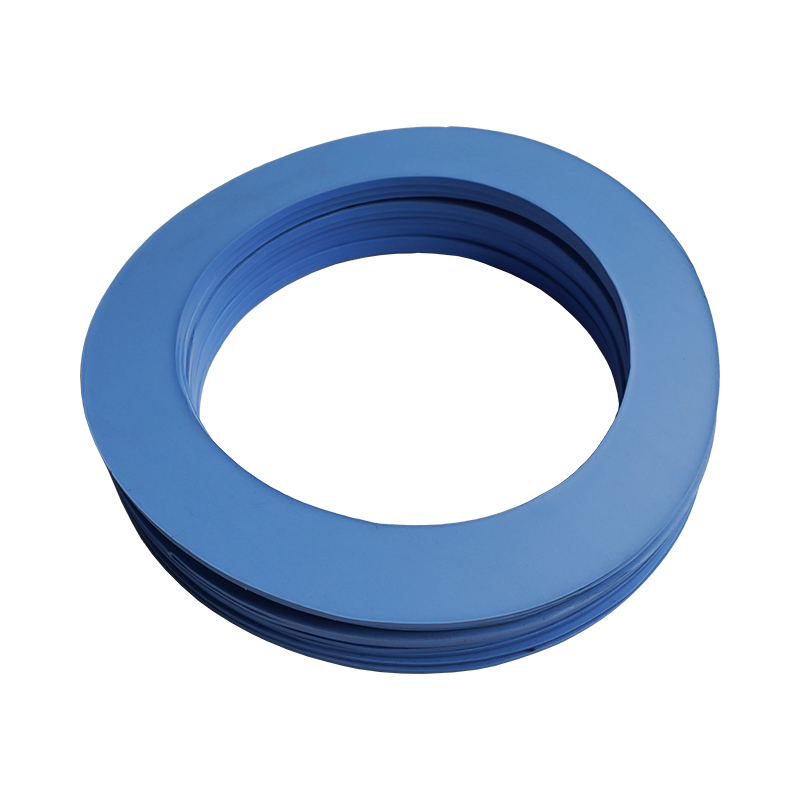

Mukauttamisvaihtoehdot

Voimme tarjota tämän materiaalin eri muodoissa vastaamaan erityisiä vaatimuksiasi:

- Räätälöityjä tiivisteitä ja muotoja

- Liima-aineettomat versiot helppoa asennusta varten

- Erityiset paksuudet vakioalueen ulkopuolella

- Yhdistelmä muiden monikerroksisten tiivisteiden materiaalien kanssa

pitää yhteyttä

-

I. Luotettavan tiivistyksen perusta Korkean panoksen teollisissa ympäristöissä – kuten sähköntuotannossa, kemiallisessa käsittelyssä ja kuljetuksessa – nesteiden luotettavasta eristämisestä ei v...

oppia lisää -

I. Johdanto: Tiivistyksen tekniset parametrit Nykyaikaisten teollisuuskoneiden erittäin vaativissa ympäristöissä – sähköntuotannon, kemian jalostuksen ja merenkulun aloilla – tiivisteiden toimin...

oppia lisää -

I. Tiivistysratkaisut äärimmäisiin teollisuusympäristöihin Kriittisissä teollisissa sovelluksissa, jotka kattavat merenkulun, sähköntuotannon, raudan ja teräksen sekä kemian, dynaamisten tiivist...

oppia lisää

Modifioitu polytetrafluorietyleenilevy: uusi aikakausi korkean suorituskyvyn materiaaleista, kuka voi pysäyttää sen teollisen sovelluksen aallon?

Aina muuttuvalla teollisuusalalla materiaalitieteen edistyminen on yksi avainvoimista, jotka johtavat teollisuuden päivittämistä. Niiden joukossa modifioitu polytetrafluorietyleenilevy (MPTFE) on erinomainen edustajana korkean suorituskyvyn materiaalien edustajana, ja se on osoittanut poikkeuksellisen käyttöpotentiaalin tiivistymisessä, korroosionkestävyydessä, kulutuskestävyydessä ja muissa kentissä, joilla on ainutlaatuiset fysikaaliset ja kemialliset ominaisuudet. Jiangsu Jintai Sealing Technology Co., Ltd. ei ole vain viljellyt perinteisiä tiivistysmateriaalimarkkinoita, vaan myös tehnyt merkittäviä saavutuksia modifioiduiden polytetrafluorietyleenilevyjen tutkimuksessa ja kehittämisessä ja tuotannossa, joka tarjoaa tehokkaita ja luotettavia tiivistysratkaisuja monille teollisuudenaloille, kuten merenkulku, sähkö, teräksinen, kemikaaliteollisuus, koneet jne. Jne.

Modifioitu polytetrafluorietyleenilevy on edistyksellinen materiaali, joka on valmistettu ottamalla käyttöön muita elementtejä tai yhdisteitä perinteisiin polytetrafluorietyleeniin (PTFE) tietyn prosessin avulla sen tiettyjen spesifisten ominaisuuksien parantamiseksi. Puhtaan PTFE: hen verrattuna MPTFE ei vain ylläpitä alkuperäistä matalaa kitkakerrointa, korkeaa kemiallista stabiilisuutta, erinomaista lämmönkestävyyttä ja kylmäkestävyyttä, vaan parantaa myös merkittävästi sen mekaanista lujuutta, kulutuskestävyyttä, hiipimäkestävyyttä ja mittastiaa, mikä on mukautuvampi monimutkaisten ja muuttuvien teollisuusympäristöjen tarpeisiin.

Jiangsu Jintai Sealing Technology Co., Ltd., joka luottaa sen syvään kertymiseen tiivistystekniikan alalla monien vuosien ajan, suhtautuu modifioidun polytetrafluorietyleenilevyjen tutkimukseen ja kehittämiseen ja tuotantoon yhtenä yrityksen strategisen kehityksen tärkeimmistä suunnista. Yrityksellä on eliitti materiaalitieteilijöitä, insinöörejä ja teknikkoja, jotka on omistettu MPTFE -materiaalien formulaation optimointiin, tuotantoprosessien parantamiseen ja uusien tuotteiden kehittämiseen. Esittelemällä edistynyttä modifikaatiotekniikkaa ja tuotantolaitteita Jintai on onnistuneesti kehittänyt sarjan modifioituja polytetrafluorietyleenialustuotteita, joilla on erinomainen suorituskyky ja täydelliset eritelmät, ja ne täyttävät tiivistysmateriaalien korkeat vaatimukset eri aloilla.

Meriympäristössä laitteiden korroosionkestävyys ja tiivistyminen ovat ratkaisevan tärkeitä. Modifioituja polytetrafluorietyleenilevyjä käytetään laajasti laivanmoottoreissa, putkilinjajärjestelmissä, venttiilin tiivisteissä ja muissa pelloilla, joilla on erinomainen korroosionkestävyys ja hyvä tiivistymisteho, jotta varmistetaan laivan navigoinnin turvallisuus.

Lämmönvaihtojärjestelmässä höyryputkilinja ja savukaasunkäsittelyjärjestelmä, korkea lämpötila, korkea paine ja syövyttävät väliaineet aiheuttavat vakavia haasteita tiivistysmateriaaleille. MPTFE -arkeista on tullut ihanteellisia tiivistysmateriaaleja näillä pelloilla erinomaisella korkean lämpötilankestävyydellä ja kemiallisella korroosionkestävyydellä.

Teräksen sulatus- ja kemiallisen tuotannon prosessissa väliaineella on usein voimakkaan syövyttävyyden, korkean lämpötilan ja korkean paineen ominaisuudet. Modifioidut polytetrafluorietyleenilevyt eivät voi vain vastustaa näitä kovia ympäristöjä tehokkaasti, vaan myös tarjota pitkäaikaisen ja vakaan tiivistysvaikutuksen, pidentäen laitteiden käyttöiän käyttöä.

Tarkkuuskoneissa ja automaatiolaitteissa on suuria vaatimuksia kulumiskestävyydelle ja osien alhaiselle kitkalle. MPTFE -arkkien levitys voi vähentää merkittävästi mekaanista kulumista, parantaa laitteiden toiminnan tehokkuutta ja vähentää huoltokustannuksia.

Tieteen ja tekniikan jatkuvan edistymisen sekä teollisten tarpeiden kasvavan monipuolistamisen myötä muokattujen polytetrafluorietyleenilevyjen markkinat ovat laajempia. Jiangsu Jintai Sealing Technology Co., Ltd. jatkaa yritysfilosofian "innovaatioiden, laadun ja palvelun" lisäämistä, tutkimus- ja kehitysinvestointien lisäämistä, syventämistä yhteistyöstä kotimaisten ja ulkomaisten tieteellisten tutkimuslaitosten kanssa ja tarjoamalla jatkuvasti korkeampia suorituskykyisiä ja arvokkaampia muokattuja polytetrafluori-asiakkaita, jotka ovat myös maalaisten tiivistymisaineisto-asiakkaideni kanssa ja myös maalaisten tiivistetyissä polytetra-aineistoimistoissa korkealaatuiset ja ammattimaiset tiivistysratkaisut.